You get several benefits when you use a blast room for surface preparation. These include safety, efficiency, cleanliness, and flexibility.

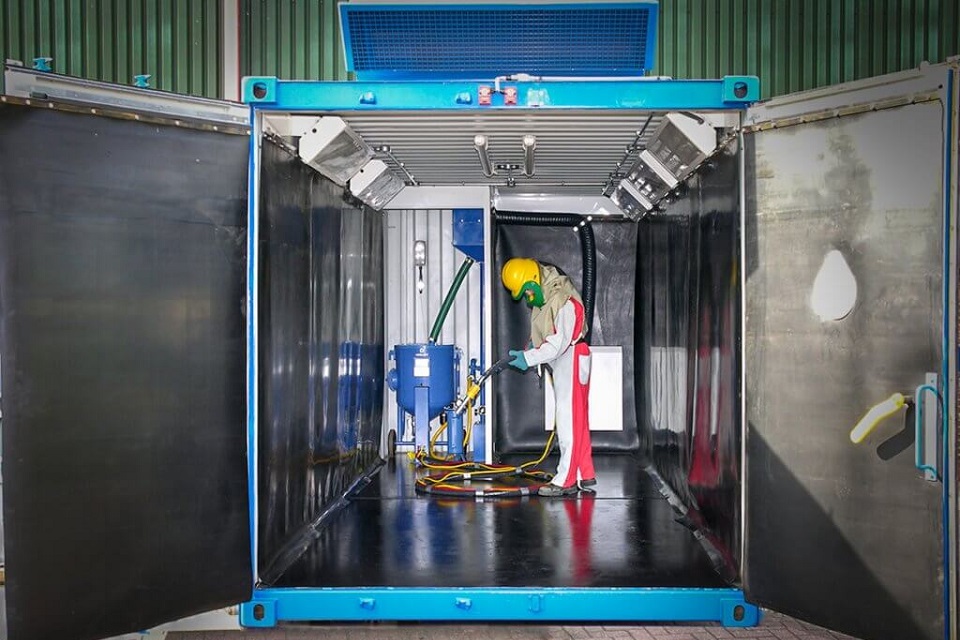

A blast room is a wholly enclosed abrasive blasting system that eliminates outdoor abrasive blasting hazards and the expense of cleaning and disposing of media. It also allows for increased throughput and a quick ROI.

Table of Contents

Cleanliness

A vast metal part, such as a tank, car, or airplane, must be blasted in a secure and efficient environment.

Blasting media, a dust collection system, ventilation, and lighting, such as Airblast AFC pre-configured rooms with various capabilities, are required equipment. Whether you need a single or multiple blast chamber solution, their streamlined design process and quick turnaround time can meet your needs.

The abrasive media is usually a mix of steel grit, sand, or both. The best way to determine what abrasive media you’ll use in your next blast job is to contact our knowledgeable media consultants for a free no, obligation discussion and analysis of your needs. We’ll recommend the abrasive media that will most likely give you the desired results. The abrasive media you choose will impact the performance of your operation and your bottom line.

Safety

Blasting rooms provide a clean and controlled environment to perform surface preparation. They can be used with abrasive or non-abrasive media and operate safely with the appropriate protective clothing and ventilation.

Dust collectors also play a crucial role in keeping the air clean and free of harmful contaminants. This is because dry blasting generates many airborne particles that can travel throughout the job site.

A sound dust collection system helps prevent these contaminants from drifting into the room, where they can affect operators working inside. These dust collectors use air filters to capture airborne particulate before it can escape into the work area.

A well-designed abrasive blast system will include an amply lit work area, an abrasive reclaim floor that begins the recycling process, an abrasive transport and separation system that removes trash while returning clean abrasive to the blast tank, and a dust collector for keeping the environment clean and contaminant free.

Efficiency

Abrasive blasting is a powerful and effective method for cleaning, stripping, and preparing surfaces for coating. It also improves productivity and reduces environmental impact.

Blasting is more efficient than manual methods because it uses less workforce and requires smaller amounts of material to achieve the desired result. Additionally, many of the abrasives used can be recycled in future operations.

Abrasive reclaim systems are one of the most important aspects of any blast room because they lower purchase and disposal costs. Whether it’s a simple “sweep-in” design or an entire complex floor reclaim, the more efficient your system is at recycling abrasives, the better off you’ll be.

Reclaim systems include a pneumatic conveying system that carries spent media to a four-stage recovery and reclaim process that consists of a cyclone centrifuge, dual adjustable air wash, magnetic separator, and vibratory screen. These combine to separate dust, debris, and contaminants from reusable media.

Flexibility

Blasting is the way to get a metal surface ready for powder coating. It removes mill scale, a previous paint coating, and rust from the metal so it can be re-coated with a quality coating.

Blast rooms come in various sizes and are designed to accommodate all types of abrasive media, including plastic. They feature a media reclaim system, dust collector, and other equipment for convenience, safety, and protection from particulate matter.

A well-designed and engineered blast room will increase your productivity and profitability. It will be configured to your plant layout, material handling methods, and the blasted workpiece’s height.

Flexibility is the ability to move painlessly through a full range of motion. It is essential for physical and sports performance. It is also an important measure of health and wellness.